Drying of apricots

Practical Action

The apricots should be picked by hand and placed carefully in a harvesting basket. The

harvesting basket and the hands of the harvester should be clean.

For the best quality dried product the apricots should be picked when they are 'eating ripe' (firm

and sweet) rather than 'juicy ripe' (soft and sweet). They should be deep yellow to golden orange

in colour.

Preparation – sorting the fruit

Damaged and bruised fruits must be rejected as they produce low quality dried apricots. Under-

ripe apricots should be rejected as these produce a bland colourless product and do not absorb

sufficient sulphur dioxide during sulphuring. Over-ripe apricots should also be rejected as they

absorb too much sulphur dioxide.

The apricots should be washed in clean water. If dried apricot halves are being produced, the

apricots should be split into two and the kernels removed. The pits (or stones) are removed by

running water through baskets full of the fruit and separating the flesh from the stone by hand.

Be careful not to squash and bruise the fruit too much during this process. The two halves of the

fruit should be separated as this produces a more attractive product than when they are left

connected. The separated pits can be cracked to obtain the kernel, which can either be

consumed or converted into cooking oil. Bitter pitted fruit can be fed to animals.

Pre-treatment

The apricots can be treated before they are dried. This is not essential but does produce a higher

quality product. There are several options for pre-treating apricots, the most effective one being

sulphuring. If you choose not to sulphur, a good alternative is syrup blanching. Apricots can also

be pre-treated by dipping them in a solution of fruit juice.

The different pre-treatment methods are described below:

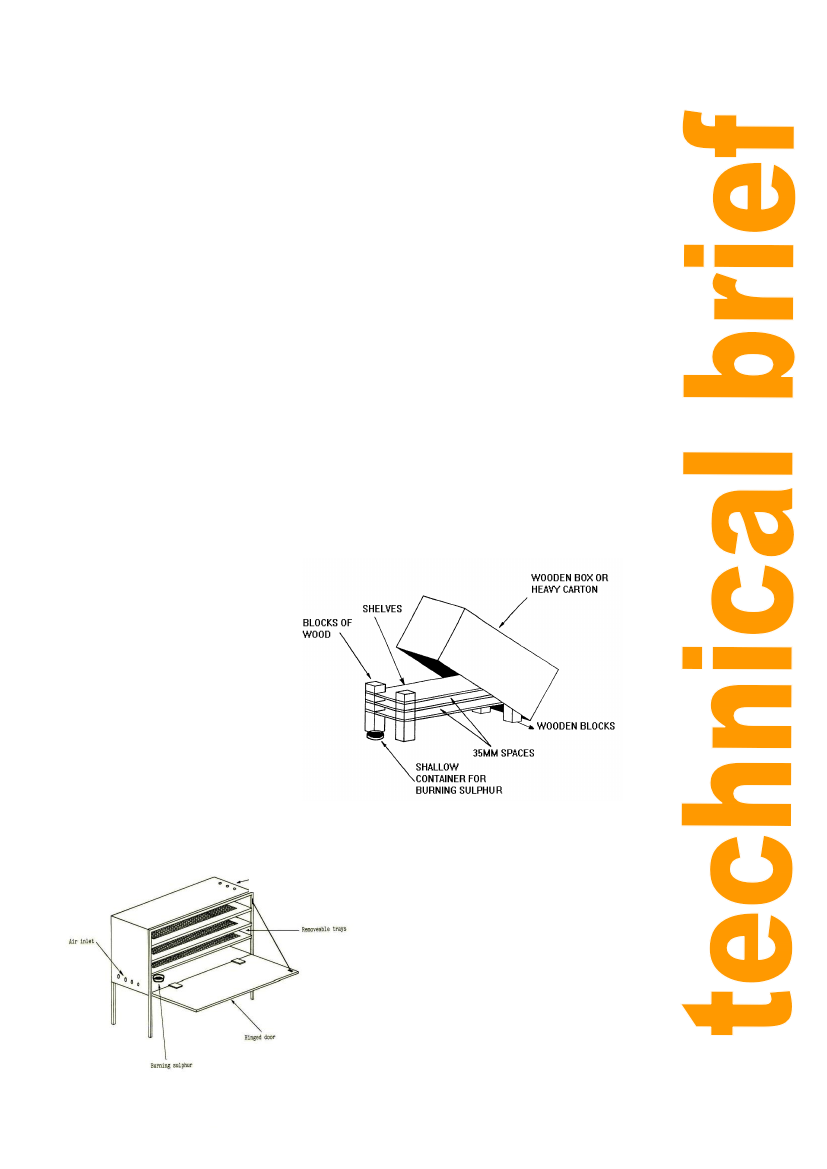

Sulphuring

Sulphur dioxide will help to

maintain the bright orange colour

of the apricots. There are two

methods of adding sulphur dioxide

to the apricots: they can be dipped

in a solution of sodium

metabisulphite (sulphiting) or they

can be placed in a chamber in

which sulphur is burnt (sulphuring)

(see Figures 2 and 3).

Sulphuring is the preferred option

because in sulphiting, there is

often an uneven penetration of

sulphur dioxide, the fruit is made

Figure 2. Traditional sulphuring

wet which increases the amount of drying

Vent holFesigure 2: Trandietieodneadl saunlpdhusorimnge soluble nutrients are lost.

Figure 3: Traditional sulphuring

2

There are strict limits regarding the amount of

sulphur that can be added (or which is

residual in the apricots after sulphuring). It is

important not to exceed this limit as the

apricots will have a sulphurous taste. The

colour of dried apricots can be regulated

without the addition of chemical preservatives

by improving the drying conditions. The

apricots need to be placed in a chamber in

which sulphur (2-4g sulphur per kg apricots)

is burnt for 2-3 hours. Figures 2 and 3 show

traditional sulphuring chambers.